Most Popular

Advantages and Disadvantages of Electric Arc Furnace and Induction Furnace Steelmaking

Advantages and Disadvantages of Electric Arc Furnace and Induction Furnace Steelmaking

Electric Arc Furnace VS Induction Furnace SteelmakingComparison of advantages and ...

Electric Arc Furnace VS Submerged Arc Furnace

Electric Arc Furnace VS Submerged Arc Furnace

Electric Arc Furnace VS Submerged Arc Furnace Direct current electric arc ...

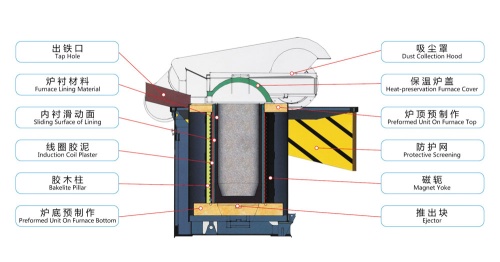

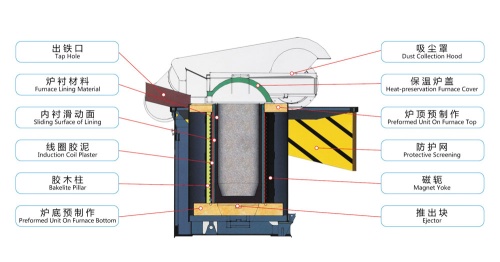

Electric Induction Furnace Diagram

Electric Induction Furnace Diagram

Electric Induction Furnace Diagram Induction furnace steelmaking is a steelmaking method that ...

Electric arc furnace steelmaking uses electric energy as heat energy and uses the high temperature of the arc generated between ...

Electric arc furnace steelmaking uses electric energy as heat energy and uses the high temperature of the arc generated between ...HAN Submerged Arc Furnace (2022-HAN Suberged Arc Furnace.pdf)

Wire Drawing Machine Technical Transformation

In the product industry, the wire rod is drawn for multiple passes by the wire drawing machine to make various specifications of steel wires for rope making and then processed by the stranding machine and the rope forming machine to finally produce various specifications of steel wire ropes. Among them, ... Read More ...

08/04/23

Wire Drawing Defects and Residual Stresses

Typical defects in a drawn rod or wire are similar to those observed in extrusion especially center cracking another major type of defect in wire drawing is seams, which are longitudinal scratches or folds in the material.Seams may open up during subsequent forming operations (such as upsetting, heading, thread rolling, or bending ... Read More ...

08/04/23

Wire Drawing Machine Wire Drawing Break Reason

Users will inevitably encounter problems such as disconnection when installing the dust removal wire drawing machine. There are many reasons for this problem. In order to help you better solve this problem, we will analyze the reasons for you today and will give you some suggestions. Let’s take a look ... Read More ...

08/04/23

Copper Wire Drawing Wire Breakage

How to Deal with the Breakage of the Copper Wire Drawing Machine During the Wire Drawing Process?The main cause of copper wire breakage is that during the wire drawing process, the copper powder accumulates and the tensile force is relatively large, and the span is too large. On the other ... Read More ...

08/04/23

Stainless Steel Wire Drawing Machine Advantages and Disadvantages

Advantages and Disadvantages of Brushed Stainless Steel in Stainless Steel Wire Drawing MachineThe stainless steel wire drawing machine is mainly used for the surface treatment of metals. The machine adopts physical properties so that the performance of the workpiece does not change during polishing. Below, we look at the pros and cons ... Read More ...

08/04/23

Elephant Trunk Type Wire Take-up Machine Features

Features and technical advantages of elephant trunk type wire take-up machineElephant trunk type wire take-up machine is a kind of equipment widely used in wire and cable production line. It has the following technical advantages and characteristics: Efficient and fast: Elephant trunk type wire take-up machine adopts advanced synchronous control ... Read More ...

05/18/23

What is Wire Drawing Manufacturing?

Metal wire drawing manufacturing is a manufacturing process in which the aluminum plate is repeatedly scraped out with sandpaper. The main process of process is divided into three parts: de-esterification, sand mill, and water washing.In the wire drawing process, the special film technology after anodizing can make the metal surface ... Read More ...

05/18/23

Straight-in Wire Drawing Machine Applicable Standards

The straight-in wire drawing machine is a non-sliding way to draw medium and low carbon steel wire, stainless steel wire, molded steel wire, and non-ferrous metal wire coarse and medium diameter and developed equipment, suitable for standard parts industry, supermarket shelf production industry, steel wire to material processing enterprises.The straight-in ... Read More ...

04/27/23

Advantages and Disadvantages of Electric Arc Furnace and Induction Furnace Steelmaking

Electric Arc Furnace VS Induction Furnace SteelmakingComparison of advantages and disadvantages of electric arc furnace and induction furnace steelmaking1. The induction furnace heats up quickly and has high thermal efficiency. The heat is generated inside the charge (steel liquid), so the heating is fast. In the arc furnace, the heat of the arc after ... Read More ...

01/31/23

Electric Induction Furnace Diagram

Electric Induction Furnace Diagram Induction furnace steelmaking is a steelmaking method that uses induction electrothermal effect to heat and melts metal. It is especially suitable for smelting a small amount of high-quality steel and alloy with high-quality raw materials (high-quality scrap steel, ferroalloy, etc.). The vacuum induction furnace equipped with a vacuum ... Read More ...

01/31/23