Most Popular

Advantages and Disadvantages of Electric Arc Furnace and Induction Furnace Steelmaking

Advantages and Disadvantages of Electric Arc Furnace and Induction Furnace Steelmaking

Electric Arc Furnace VS Induction Furnace SteelmakingComparison of advantages and ...

Electric Arc Furnace VS Submerged Arc Furnace

Electric Arc Furnace VS Submerged Arc Furnace

Electric Arc Furnace VS Submerged Arc Furnace Direct current electric arc ...

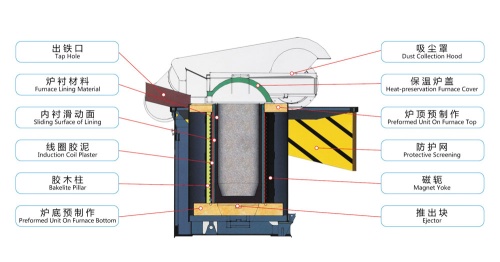

Electric Induction Furnace Diagram

Electric Induction Furnace Diagram

Electric Induction Furnace Diagram Induction furnace steelmaking is a steelmaking method that ...

Electric arc furnace steelmaking uses electric energy as heat energy and uses the high temperature of the arc generated between ...

Electric arc furnace steelmaking uses electric energy as heat energy and uses the high temperature of the arc generated between ...HAN Submerged Arc Furnace (2022-HAN Suberged Arc Furnace.pdf)

Electric Arc Furnace VS Submerged Arc Furnace

Electric Arc Furnace VS Submerged Arc Furnace

Direct current electric arc furnace and direct current submerged arc furnace are industrial furnaces that directly heat the charge with the heat of arc light. When the gas is ionized to form a conductive ion body, the gas column produces a strong bright light and extremely high temperature, which is the arc light. The temperature of the arc core is as high as 10,000 degrees Celsius, and the temperature of the arc periphery is as high as 3,000 degrees Celsius. It is easier to obtain such a high-temperature heat source by means of arc light than by other methods. Therefore, in production, people often use electric arc furnaces to smelt ores to obtain various rare metals and ferroalloys.

There is an essential difference between DC arc and AC arc: AC current crosses zero twice in each cycle, resulting in AC arc going through the arc starting and extinguishing process twice a week, the arc is unstable; There is no arc extinction after the DC arc starts, and the arc light is very stable.

In electric arc smelting, if the arc is not buried by the slag and charge and the arc can be seen, it is called an open arc; if the arc is buried by the slag and charge and the arc is invisible, it is called a submerged arc.

If a DC electric furnace is used to melt steel, no slag is formed, and the solid materials themselves are conductive and work in the form of an open arc. Such a working form is called DC electric arc furnace.

If the direct current furnace is used to smelt non-conductive ore, the solid material itself is not conductive, and a large amount of slag is produced during the smelting process. These slag and charge cover the electric arc and form a submerged arc state. Such a working form is called a direct current submerged arc furnace.

Compared with AC electric furnace, DC electric furnace has the following advantages:

1. Save 1~2 sets of electrode devices than AC electric furnace.

Since the AC furnace uses a three-phase power supply, 3 graphite electrodes are required. The direct current furnace only uses 1 to 2 graphite electrodes.

2. The consumption of graphite electrodes can be saved by 30% to 50%.

Compared with AC arc, DC arc can work under high impedance, DC electric furnace can work stably with higher voltage and low current mode at the same input power, which can reduce electrode tip consumption proportional to the square of the current.

The side loss of the electrode is mainly due to oxidative burning loss. In this regard, the AC electric furnace is significantly higher than the DC electric furnace.

3. There is no skin effect problem, and the current can be evenly distributed in the electrode section.

4. Long service life of refractory material for furnace wall.

The arc of the AC electric furnace is generated between the three-phase electrodes. Due to the electromagnetic force generated by the arc current itself, the arc is pushed to the furnace wall by the electromagnetic force, and hot spots are formed on the furnace wall, which easily leads to the refractory of the furnace wall at the hot spots. The material is eroded seriously and damaged prematurely.

The arc of the DC electric furnace is generated between the electrode and the furnace bottom, and will not form hot spots on the furnace wall and will not damage the furnace wall.

5. The charge is melted evenly.

The arc of the DC electric furnace is a vertical center, with uniform heat distribution and uniform melting of the charge. The three-phase arc of the AC electric furnace is of lateral form, and the three-phase arcs influence each other, and the melting of the charge is uneven.

6. Stable DC arc current.

The AC current crosses zero 100 times per second, which means that there are 100 times of arc extinguishing, arc striking, arc extinguishing, and arc striking again, resulting in unstable AC arcs. The DC current is only zero point and there is no change in polarity, so the DC arc is more stable than the AC arc.

7. The power factor of the AC electric furnace is low, generally 0.68~0.75, and the power factor of the DC electric furnace is high, generally 0.96.

8. Low energy consumption; can save electricity consumption by 5% to 10%.

9. Frequent fluctuations in the reactive power of AC electric furnaces cause grid voltage flicker. In order to solve the flicker effect and compensate for the impact of harmonics on the grid, AC electric furnaces need expensive reactive power compensation devices. There is no such phenomenon in the DC electric furnace, and no reactive power compensation device is required.

10. The change of the arc length of the three-phase arc of the AC electric furnace is inconsistent in time, which causes the three-phase load to be asymmetrical, which has great interference and impact on the power grid. DC electric furnace does not have this phenomenon.

11. Stirring effect on molten steel.

Because the direction of the DC current remains unchanged, the DC arc has a strong stirring effect on the molten steel, so that there is no dead angle in the melting of the charge, while the AC arc does not.

12. The noise of the DC electric arc furnace is 20dB lower than that of the AC electric arc furnace of the same capacity. The DC electric furnace is no noise during the submerged arc stage.

More News You May Interesting:

Nine Ways to Save Electricity in Steel-making Electric Furnace

Melting Features of Medium Frequency Electric Furnace

EAF Steelmaking Cleaner Production Technology

The Function and Working Principle of Rolling Mill Heating Furnace

How Does Electric ARC Furnace Work?(B)

How Does Electric ARC Furnace Work?(A)

What are the Advantages and Disadvantages of Blast Furnace?

Characteristics of Electric Arc Furnace Steelmaking

Walking Beam Reheating Furnace VS Push-steel Reheating Furnace

Why Intermediate Frequency Furnace cannot be Turned on Normally?

The History of Electric Arc Furnace