Most Popular

Advantages and Disadvantages of Electric Arc Furnace and Induction Furnace Steelmaking

Advantages and Disadvantages of Electric Arc Furnace and Induction Furnace Steelmaking

Electric Arc Furnace VS Induction Furnace SteelmakingComparison of advantages and ...

Electric Arc Furnace VS Submerged Arc Furnace

Electric Arc Furnace VS Submerged Arc Furnace

Electric Arc Furnace VS Submerged Arc Furnace Direct current electric arc ...

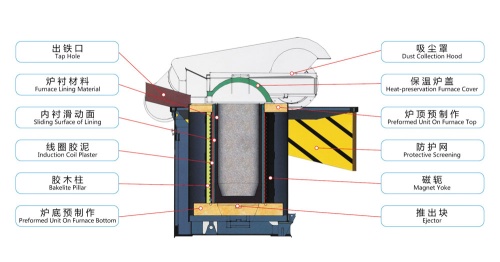

Electric Induction Furnace Diagram

Electric Induction Furnace Diagram

Electric Induction Furnace Diagram Induction furnace steelmaking is a steelmaking method that ...

Electric arc furnace steelmaking uses electric energy as heat energy and uses the high temperature of the arc generated between ...

Electric arc furnace steelmaking uses electric energy as heat energy and uses the high temperature of the arc generated between ...HAN Submerged Arc Furnace (2022-HAN Suberged Arc Furnace.pdf)

Stainless Steel Wire Drawing Machine Advantages and Disadvantages

Advantages and Disadvantages of Brushed Stainless Steel in Stainless Steel Wire Drawing Machine

The stainless steel wire drawing machine is mainly used for the surface treatment of metals. The machine adopts physical properties so that the performance of the workpiece does not change during polishing. Below, we look at the pros and cons of brushed stainless steel.

Stainless Steel Wire Drawing Machine

Advantages of Brushed Stainless Steel in Stainless Steel Wire Drawing Machine

- Simple and elegant, reducing unnecessary decorative lines, thus increasing the openness of the overall kitchen space. Equipment such as sinks, stoves, and range hoods made of the same material can also be embedded in it more subtly, making it feel integrated.

- Stainless steel adheres to the advantages of metal materials and has good toughness. Traditional cabinets are not easy to waterproof and moisture-proof. If they are exposed to moisture or water for a long time, they will swell and burst, and things that encounter acid and alkali will corrode and rot. But good stainless steel cabinets don’t have to worry about these.

- Bright, clean, fireproof, easy to clean, with a typical metal fashion sense and strong practicability.

- There are various colors and styles. There are many colors of stainless steel cabinets, such as silver gray, silver white, golden yellow, dark blue, etc. No matter it is exposed to wind and rain or after a long period of storage, it will not change color.

Disadvantages of Brushed Stainless Steel in Stainless Steel Wire Drawing Machine

- Brushed stainless steel is prone to oxidation, which will shorten the service life of stainless steel;

- The surface of the brushed stainless steel product is scratched and it is difficult to recombine. After a long time, bacteria will remain in the scratched cracks, so you must pay more attention when cleaning.

The above is the introduction of “the advantages and disadvantages of brushed stainless steel in Stainless Steel Wire Drawing Machine”.

YF Metal Tech focuses on the R&D and manufacturing of wire drawing machines and polishing machines,

At present, we can provide a variety of high-quality wire drawing machine equipment, including stainless steel wire drawing machines, automatic wire drawing machines, plane wire drawing machines, water mill wire drawing machines, etc. Welcome to consult.

Article Source: Stainless Steel Wire Drawing Machine Advantages and Disadvantages

More Articles You May Interesting:

Automatic Wire Drawing Machine VS Manual Drawing Machine

Automatic Nail Making Machine Working Principle

Cemented Carbide Wire Drawing Die Manufacturing Process

Precautions for Wire Drawing Machine Operation

Wire Drawing Machines: Spray Welding VS Tungsten Carbide Thermal Spraying

What is Elephant Trunk Take-up Machine?

Six Types Wire Drawing Machines

Copper Wire Drawing Machine Production Process

Wire Drawing Machine Structure Device

Advantages of Inverted Wire Drawing Machine

High Speed Wet Wire Drawing Machine Operation Steps

Wire Drawing Products Unqualified Surface Quality Reasons

Wet Wire Drawing Machine Working Principle

Wet Drawing Machine Transformation Process Requirements