Most Popular

Advantages and Disadvantages of Electric Arc Furnace and Induction Furnace Steelmaking

Advantages and Disadvantages of Electric Arc Furnace and Induction Furnace Steelmaking

Electric Arc Furnace VS Induction Furnace SteelmakingComparison of advantages and ...

Electric Arc Furnace VS Submerged Arc Furnace

Electric Arc Furnace VS Submerged Arc Furnace

Electric Arc Furnace VS Submerged Arc Furnace Direct current electric arc ...

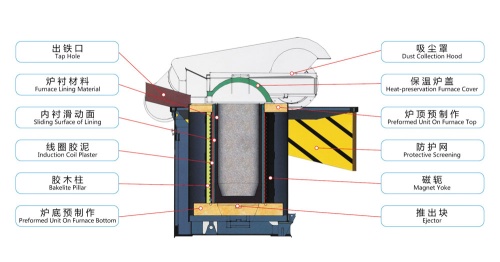

Electric Induction Furnace Diagram

Electric Induction Furnace Diagram

Electric Induction Furnace Diagram Induction furnace steelmaking is a steelmaking method that ...

Electric arc furnace steelmaking uses electric energy as heat energy and uses the high temperature of the arc generated between ...

Electric arc furnace steelmaking uses electric energy as heat energy and uses the high temperature of the arc generated between ...HAN Submerged Arc Furnace (2022-HAN Suberged Arc Furnace.pdf)

Straight-in Wire Drawing Machine Applicable Standards

The straight-in wire drawing machine is a non-sliding way to draw medium and low carbon steel wire, stainless steel wire, molded steel wire, and non-ferrous metal wire coarse and medium diameter and developed equipment, suitable for standard parts industry, supermarket shelf production industry, steel wire to material processing enterprises.

The straight-in wire drawing machine mainly comprises frame, reducer box, reel, drop wire frame, carriage, pneumatic system, communication frequency control electric control system, and motor.

The reel is placed upside down in the lower part of the reduction box, and the drawn wire can be collected directly to the drop wire frame, and then the end of the large tray collects the wire again.

The drive system of the straight-in wire drawing machine uses a powerful narrow V-belt combination hardened gear reducer or oscillating ring reducer; the wire collecting plate is serious; the reel is forced air cooled; the pneumatic pressure wheel; the lower wire plate is independently driven and the diameter of the lower wire coil is adjustable; the communication frequency conversion speed control makes the machine easy to operate, safe and reliable, and saves more than 30% of energy.

Straight into the wire drawing machine in the motor through the pulley and three-stage gear drive, driving the reel placed on the reducer box rotation output shaft, traction wire end pulling.

After pulling the wire through the lead roller, into the drop wire frame, the drop wire frame and reel synchronous rotation.

The straight-in wire drawing machine is highly automated and can draw and collect wires together.

The wire collecting plate can be as large as 2 tons, easy and reliable to unload, simple operation, high production efficiency, safe, and reliable; it can be positively rotated and decontrolled when the whole machine is running, so as to avoid the formation of accidents by mistake; the appearance is neat and beautiful.

Article Source: Straight-in Wire Drawing Machine Applicable Standards

More Articles You May Interesting:

What is a Metal Drawing Machine?

Straight-in Wire Drawing Machine Applicable Standards

Wet Drawing Machine Transformation Process Requirements

Wet Wire Drawing Machine Working Principle

High Speed Wet Wire Drawing Machine Operation Steps

Advantages of Inverted Wire Drawing Machine

Wire Drawing Machine Structure Device