Most Popular

Advantages and Disadvantages of Electric Arc Furnace and Induction Furnace Steelmaking

Advantages and Disadvantages of Electric Arc Furnace and Induction Furnace Steelmaking

Electric Arc Furnace VS Induction Furnace SteelmakingComparison of advantages and ...

Electric Arc Furnace VS Submerged Arc Furnace

Electric Arc Furnace VS Submerged Arc Furnace

Electric Arc Furnace VS Submerged Arc Furnace Direct current electric arc ...

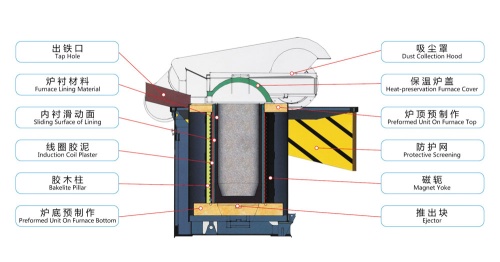

Electric Induction Furnace Diagram

Electric Induction Furnace Diagram

Electric Induction Furnace Diagram Induction furnace steelmaking is a steelmaking method that ...

Electric arc furnace steelmaking uses electric energy as heat energy and uses the high temperature of the arc generated between ...

Electric arc furnace steelmaking uses electric energy as heat energy and uses the high temperature of the arc generated between ...HAN Submerged Arc Furnace (2022-HAN Suberged Arc Furnace.pdf)

Copper Wire Drawing Wire Breakage

How to Deal with the Breakage of the Copper Wire Drawing Machine During the Wire Drawing Process?

The main cause of copper wire breakage is that during the wire drawing process, the copper powder accumulates and the tensile force is relatively large, and the span is too large. On the other hand, the size of the wire drawing is relatively small and easy to break.

In the process of production, sometimes there will be frequent broken wires. If the sizing area of the wire drawing dies becomes larger due to wear and tear, then this problem can be easily solved as long as you pay attention to prevent it and do a good job of inspection.

It may also be caused by the instability of the current, so it is necessary to pay attention to whether the annealing current is stable. This should be constantly paid attention to during the production process, especially when it is just started, especially pay attention to the change of the current, and adjust it according to the change of the line speed. The current size of the return.

Due to the uninterrupted production of copper wire drawing equipment, the speed of wire drawing will gradually be out of sync with annealing, which will cause intermittent and irregular changes in wire diameter due to the fast and slow speed of drawing during wire drawing. The reasons for the phenomenon are as follows:

- The tension on the wire storage wheel is unstable. There may be many places where the air pressure is used in the production workshop, which will cause the air pressure of the air pump of the wire drawing machine to vary from time to time. The tensile force suffered by the wire drawing is also not constant, which can cause the deviation of the outer diameter of the single wire to be unable to be accurately controlled.

- The vibration of the copper wire on the annealing wheel. This makes the copper wire be annealed in state of sometimes loose and sometimes tight, and the annealing current density is sometimes high and sometimes small, and the strength of the copper wire at a higher speed is relatively low, so it is easy to cause the copper wire to spark on the annealing wheel so that the surface of the copper wire is uneven in diameter due to the action of sparks.

- Wear and tear caused by the long-term use of the main motor gearbox. This can make the speed of the fixed speed wheel of the wire drawing not match the pulling speed and the wire take-up speed, thereby forming a thinning of the monofilament.

Solution: Lubricate the wire storage device well to avoid reverse friction on the wire during high-speed operation and make the wire thinner;

Adjust the tension of the wire so that the drawing stroke is always close to the annealing wheel;

Ensure the integrity of the steel ring of the annealing wheel, and avoid the instability of the annealing current due to the surface defects of the steel ring.

According to the actual situation of the copper wire drawing machine, re-match the wire drawing machine: adjust according to the wire drawing principle, so that the speed of the annealing wheel/the speed of the fixed speed wheel=the forward slip coefficient×the diameter of the fixed speed wheel/the diameter of the annealing wheel, among which the fixed speed wheel and the annealing wheel The diameter of the wire drawing machine is known, and the speed of the fixed speed wheel and the annealing wheel can also be measured, so that the forward slip coefficient can be obtained, and the wire drawing machine can be reconfigured according to the slip coefficient, so that the mold can meet the requirements.

Article Source: Copper Wire Drawing Wire Breakage

More Articles You May Interesting:

Automatic Wire Drawing Machine VS Manual Drawing Machine

Automatic Nail Making Machine Working Principle

Cemented Carbide Wire Drawing Die Manufacturing Process

Precautions for Wire Drawing Machine Operation

Wire Drawing Machines: Spray Welding VS Tungsten Carbide Thermal Spraying

What is Elephant Trunk Take-up Machine?

Six Types Wire Drawing Machines

Copper Wire Drawing Machine Production Process

Wire Drawing Machine Structure Device

Advantages of Inverted Wire Drawing Machine

High Speed Wet Wire Drawing Machine Operation Steps

Wire Drawing Products Unqualified Surface Quality Reasons

Wet Wire Drawing Machine Working Principle

Wet Drawing Machine Transformation Process Requirements