Most Popular

Advantages and Disadvantages of Electric Arc Furnace and Induction Furnace Steelmaking

Advantages and Disadvantages of Electric Arc Furnace and Induction Furnace Steelmaking

Electric Arc Furnace VS Induction Furnace SteelmakingComparison of advantages and ...

Electric Arc Furnace VS Submerged Arc Furnace

Electric Arc Furnace VS Submerged Arc Furnace

Electric Arc Furnace VS Submerged Arc Furnace Direct current electric arc ...

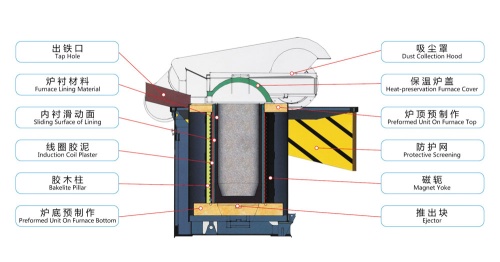

Electric Induction Furnace Diagram

Electric Induction Furnace Diagram

Electric Induction Furnace Diagram Induction furnace steelmaking is a steelmaking method that ...

Electric arc furnace steelmaking uses electric energy as heat energy and uses the high temperature of the arc generated between ...

Electric arc furnace steelmaking uses electric energy as heat energy and uses the high temperature of the arc generated between ...HAN Submerged Arc Furnace (2022-HAN Suberged Arc Furnace.pdf)

The Proportion of Raw Materials for Smelting High-carbon Ferrochromium

The Proportion of Raw Materials for Smelting High-carbon Ferrochromium

The production methods of high carbon ferrochrome include the electric furnace method, shaft furnace (blast furnace) method, plasma method, and smelting reduction method.

The raw materials for smelting high-carbon ferrochrome are chrome ore, coke, and silica.

The Proportion of Raw materials for Smelting High-carbon Ferrochromium

In chrome ore, Cr2O3≥40%, Cr2O3/∑FeO≥2.5, S<0.05%, P<0.07%, the content of MgO and Al2O3 should not be too high, and the particle size should be 10~70mm. For refractory ore, the particle size should be appropriately smaller.

Coke requires no less than 84% fixed carbon, less than 15% ash, S<0.6%, and particle size 3-20mm.

Silica is required to contain SiO2≥97%, Al2O3≤1.0%, good thermal stability, no soil, and particle size 20~80mm.

The principle of chromium ore matching: In the actual production of high-carbon ferrochromium, it is often necessary to select the appropriate mineral collocation and matching ratio.

The Main Principles of Chromium Ore Matching are:

1) Appropriate Ratio of Chromium to Iron ( Cr2o3/∑FeO).

Generally speaking, smelting alloys with chromium content greater than 50% require that the ratio of Cr2o3/ΣFeO into the furnace is greater than 2.0; while smelting alloys with chromium content greater than 60% requires this ratio to be greater than 2.6.

2) Appropriate MgO/Al2o3 Ratio.

It not only affects the conductivity and reduction properties of the slag but also affects the carbon-containing disk of the alloy.

In actual production, MgO/Al2o3 is used. Chrome ore with a low ratio needs to be equipped with sufficient coke to increase the thickness of the coke layer. On the one hand, it is to ensure that the bottom of the furnace is not easily damaged, and on the other hand, it is also to increase the unreduced core. The residence time in the coke layer. Reduce chromium in the slag.

3) Appropriate Size Matching.

When the fine ore is used alone, it is easy to cause the fine ore to sinter, make the air permeability of the material surface worse, and seriously damage the smelting atmosphere; the use of large chromium ore is easy to increase the thickness of the refining layer, resulting in the low carbon content of the alloy.

4) Appropriate Melting Performance.

The simple use of fusible chromium ore will cause slag to form prematurely, which will make the melting speed faster than the reduction speed, and will easily cause the phenomenon of high chromium in the slag; the simple use of refractory chromium ore will thicken the refining layer, and a large number of unreduced ore cores and alloys will appear. Low carbon content and other phenomena have brought great difficulties to normal smelting.

A reasonable mix of chromium ore to make the slag have a reasonable melting point is very important for improving economic indicators.

Free send inquiry to [email protected] if any needs.

Whatsapp/Wechat:+8615877652925

Website: https://www.hanrm.com

Furnace Transformer – Electric Arc Furnace

Melting Features of Medium Frequency Electric Furnace

Electric Arc Furnace VS The Intermediate Frequency Furnace

What are the Advantages and Disadvantages of Blast Furnace?

Characteristics of Electric Arc Furnace Steelmaking

Walking Beam Reheating Furnace VS Push-steel Reheating Furnace

Why Intermediate Frequency Furnace cannot be Turned on Normally?