Most Popular

Advantages and Disadvantages of Electric Arc Furnace and Induction Furnace Steelmaking

Advantages and Disadvantages of Electric Arc Furnace and Induction Furnace Steelmaking

Electric Arc Furnace VS Induction Furnace SteelmakingComparison of advantages and ...

Electric Arc Furnace VS Submerged Arc Furnace

Electric Arc Furnace VS Submerged Arc Furnace

Electric Arc Furnace VS Submerged Arc Furnace Direct current electric arc ...

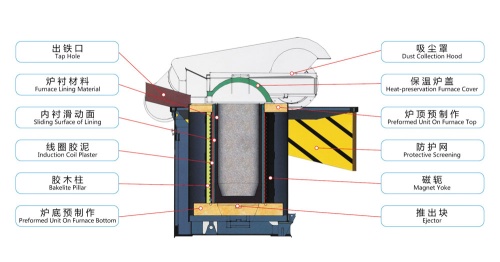

Electric Induction Furnace Diagram

Electric Induction Furnace Diagram

Electric Induction Furnace Diagram Induction furnace steelmaking is a steelmaking method that ...

Electric arc furnace steelmaking uses electric energy as heat energy and uses the high temperature of the arc generated between ...

Electric arc furnace steelmaking uses electric energy as heat energy and uses the high temperature of the arc generated between ...HAN Submerged Arc Furnace (2022-HAN Suberged Arc Furnace.pdf)

Hani Metallurgy signed a bar production line with an annual output of 1.5 million tons with Myanmar.

Hani Metallurgy signed a bar production line with an annual output of 1.5 million tons with Myanmar.

Nowadays, many energy companies are committed to providing professional metallurgical machinery equipment and services for large and medium-sized steel companies at home and abroad, such as Hani Metallurgy focuses on metallurgical machinery manufacturing, electrical automation technology research and manufacturing, has a complete R&D, production, and quality assurance system, the product quality is excellent, the operation is stable, the production efficiency has been greatly improved, and it has been recognized by the market and praised by customers.

In 2017, Hani Metallurgy signed a bar production line with an annual output of 1.5 million tons in Myanmar. The rolling mill adopts a fully continuous layout and covers automatic control technology, low-temperature rolling technology, controlled rolling, and controlled cooling technology, etc. The process plan is advanced and the site is utilized. The successful implementation of the project is inseparable from the technical support of high standards and low cost and strict control. In practice, the core competitiveness of the company is continuously improved, the product value chain is thickened, and an important strategic layout for high-quality development is achieved.

In 2018, Hani Metallurgy signed a complete set of electric arc furnace equipment with a Spanish customer. The product has low power consumption, safety and stability, easy operation, high arc starting efficiency, and diversified dust removal systems. The project has been delivered on schedule with quality and quantity. Recognized and praised, sold several sets of conductive cross arms, furnace bottoms, and other accessories in the same year.

In 2019, Hani Metallurgy signed a contract with Pakistani customers for a continuous casting machine equipped with an annual output of 500,000 tons, and in the following year, under the guidance of the Belt and Road policy, it quickly won a bar production line with an annual output of 500,000 tons in the China-Pakistan Business Park.

When the project was basically implemented, it was a period of the high incidence of the new crown epidemic in China, and then the epidemic spread to the world. Customers could not come to China for on-site inspections, and the project team could not go abroad for business and technical negotiations. They could only communicate through video conferences and emails. After many difficulties, the company successfully completed the installation and commissioning guidance with advanced technology, rich and solid international engineering experience, and high customer-oriented service standards, and the project came to a successful conclusion.

In 2020, Hani Metallurgy signed a contract with the Gulf countries for a medium-broadband production line with an annual output of 120 tons, which can provide complete production lines of various specifications and capacities, and has an absolute advantage in terms of cost performance. The construction content includes engineering design, complete equipment supply, equipment Commissioning, performance assessment, and acceptance, as well as providing technical guidance and related technical training for selection and adoption by other developing countries along the “Belt and Road”.

In 2021, Hani Metallurgy signed a contract with another Iran for two high-speed wire rod production lines with an annual output of 300,000 tons and 600,000 tons respectively. The high-speed bar production line adopts the concept of flexible and modular rolling and applies the world’s first single pass-shaped high-speed bar rolling technology, the speed can reach 45m/s stably, realizing a new breakthrough in the intelligent technology of high-speed bar and wire.

In July 2021, good news came from Iran. Hani Metallurgy provided Zhende Steel with a high-speed wire rod production line with an annual output of 500,000 tons and a high-speed strip steel production line with an annual output of 800,000 tons. The equipment running speed was 110m/s, and the product accuracy And quality have reached an internationally advanced level.

In the first quarter of 2022, Hani Metallurgy signed a complete set of electric arc furnace equipment with a state-owned foreign trade company in Beijing. The project is in production, and engineers will be arranged for on-site installation, commissioning, and technical guidance in the later delivery; in the second quarter, it signed a contract with a German steel company. The ladle refining furnace equipment has signed the DC motor equipment with the Egyptian customer and has completed the booking and delivery, waiting for the follow-up finishing work.

In the future, Hani Metallurgy will continue to contribute more high-quality metallurgy equipment as always.

More Articles You May Interesting:

The Development Trends and Advantages of Electric Arc Furnaces

The Advantage and Disadvantages of Electric Arc Furnaces and Induction Furnaces

The Advantage of an Induction Furnace (Medium Frequency Furnace)

Furnace Transformer – Electric Arc Furnace