Most Popular

Advantages and Disadvantages of Electric Arc Furnace and Induction Furnace Steelmaking

Advantages and Disadvantages of Electric Arc Furnace and Induction Furnace Steelmaking

Electric Arc Furnace VS Induction Furnace SteelmakingComparison of advantages and ...

Electric Arc Furnace VS Submerged Arc Furnace

Electric Arc Furnace VS Submerged Arc Furnace

Electric Arc Furnace VS Submerged Arc Furnace Direct current electric arc ...

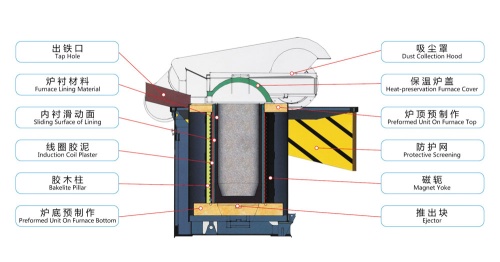

Electric Induction Furnace Diagram

Electric Induction Furnace Diagram

Electric Induction Furnace Diagram Induction furnace steelmaking is a steelmaking method that ...

Electric arc furnace steelmaking uses electric energy as heat energy and uses the high temperature of the arc generated between ...

Electric arc furnace steelmaking uses electric energy as heat energy and uses the high temperature of the arc generated between ...HAN Submerged Arc Furnace (2022-HAN Suberged Arc Furnace.pdf)

Hani Metallurgy has Commissioning Two Wire Rod Mill Pant in Iran with Annual output of 900,000 TPY In 2021

Hani Metallurgy has Commissioning Two Wire Rod Mill Pant in Iran with Annual output of 900,000 TPY In 2021

In 2021, Hani Metallurgy commissioned another Iran for two high-speed wire rod production lines with an annual output of 300,000 tons and 600,000 tons respectively.

The high-speed bar production line adopts the concept of flexible and modular rolling and applies the world's first single pass-shaped high-speed bar rolling technology, the speed can reach 45m/s stably, realizing a new breakthrough in the intelligent technology of high-speed bar and wire.

In July 2021, good news came from Iran. Hani Metallurgy provided Zhende Steel with a high-speed wire rod production line with an annual output of 500,000 tons and a high-speed strip steel production line with an annual output of 800,000 tons. The equipment running speed was 110m/s, and the product accuracy And quality have reached an internationally advanced level.

When the project was basically implemented, it was a period of the high incidence of the new crown epidemic in China, and then the epidemic spread to the world. Customers could not come to China for on-site inspections, and the project team could not go abroad for business and technical negotiations. They could only communicate through video conferences and emails.

After many difficulties, the company successfully completed the installation and commissioning guidance with advanced technology, rich and solid international engineering experience, and high customer-oriented service standards, and the project came to a successful conclusion.

In the future, Hani Metallurgy will continue to contribute more high-quality metallurgy equipment as always.

More News You May Interesting:

Why does the Steel Bar Bend after being Cut by Flying Shear?

Headless Welding Rolling Process

Bar Rolling Mills Water Cooling Technology

How to Improve the Thermal Efficiency of the Reheating Furnaces?

Causes of Surface Cracks in High-Speed Wire Rod Rolling Mill

What is Slit Rolling?

Failure Analysis of Cold Mill Roll

Causes and Solution of Steel Piling-up in High-speed Wire Rod Rolling Mills?

Bar Automatic Counting System

Rolling Mill Pass Design