Most Popular

Advantages and Disadvantages of Electric Arc Furnace and Induction Furnace Steelmaking

Advantages and Disadvantages of Electric Arc Furnace and Induction Furnace Steelmaking

Electric Arc Furnace VS Induction Furnace SteelmakingComparison of advantages and ...

Electric Arc Furnace VS Submerged Arc Furnace

Electric Arc Furnace VS Submerged Arc Furnace

Electric Arc Furnace VS Submerged Arc Furnace Direct current electric arc ...

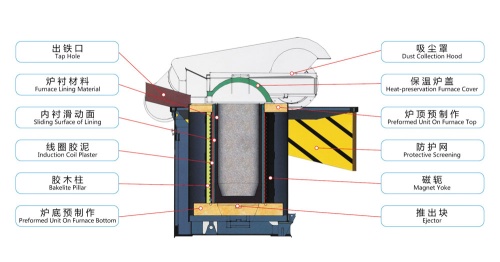

Electric Induction Furnace Diagram

Electric Induction Furnace Diagram

Electric Induction Furnace Diagram Induction furnace steelmaking is a steelmaking method that ...

Electric arc furnace steelmaking uses electric energy as heat energy and uses the high temperature of the arc generated between ...

Electric arc furnace steelmaking uses electric energy as heat energy and uses the high temperature of the arc generated between ...HAN Submerged Arc Furnace (2022-HAN Suberged Arc Furnace.pdf)

Characteristics of Forged Steel Cold Rolls (Cold Rolling Work Rolls, Cold Rolling Intermediate Rolls)

Characteristics of Forged Steel Cold Rolls (Cold Rolling Work Rolls, Cold Rolling Intermediate Rolls)

1. Carbide Hardness is High.

The cold rolling work rolls and cold rolling intermediate rolls used in the past are mostly Fe3C type or M7C3 type eutectic carbides distributed on the substrate, and the structure is coarse and the hardness is low. Forged steel cold rolls generally use high-C, high-V high-speed steel, and also contain more alloying elements such as Cr, Mo, W, Nb, and Co. These alloying elements are formed once and twice during solidification and heat treatment. carbide. The high chromium cast iron roll carbides are M7C3 (2500 Hv) and M23C6 (1600 Hv). In the infinite chill cold-rolling work roll and the cold-rolled intermediate roll, the carbide is Fe3C (l300 Hv). The forged steel cold roll mainly contains MC (3000 Hv), M7C3 (2500 Hv), and M6C (2000 Hv), which can replace the ordinary cold rolling work roll and cold rolling intermediate roll, thereby improving the wear resistance. In addition, as the V content increases, the skeletal M6C type carbide in the high-speed steel structure is converted to the granular VC type.

2. Good Thermal Stability.

The forged steel cold roll contains more elements such as W, Cr, Mo, V, and Nb, and has good thermal stability. It is found that the hardness of the ordinary roll material decreases significantly with the increase of temperature, while the forged steel cold roll Maintaining 500 Hv at 600 ° C will greatly improve the wear resistance of the rolls. This tendency is more pronounced especially when the Co element distributed in the matrix structure is added.

3. It is Easy to Form an Oxide Film During Use.

In the rolling process, if a continuous, dense, uniform, and good adhesion oxide film is formed on the surface of the roll, the friction coefficient between the roll and the rolled material can be reduced, and the dimensional accuracy and surface quality of the rolled material can be improved. Ordinary rolls are worn at an early stage due to the absence of oxide film protection and wear. In the use of forged steel cold roll, the oxide film can be formed quickly, and the appearance of the oxide film can reduce the friction between the strip and the surface of the roll, prevent the roll from sticking to the steel, and improve the life of the roll. Compared with ordinary rolls, the initial wear of the forged steel cold rolls is lower, which is very advantageous for improving the wear resistance of the forged steel cold rolls.

4. Good Hardenability.

The forged steel cold roll has good hardenability. At room temperature, within 50mm of the working layer, the hardness drop from the surface of the roll to the core is less than 3HS, which ensures that the roll has good wear resistance from the outside to the inside.

5. Excellent Strength and Toughness.

Compared with general infinite chilled cast iron, high chromium cast iron, and semi-steel rolls, the forged steel cold roll has better basic mechanical tensile strength and fracture toughness than high chromium cast iron rolls and infinite chilled cast iron rolls, and semi-steel. The rolls are close.

6. Good Resistance to Thermal Cracking.

High-speed steel can effectively inhibit the formation and expansion of cracks due to its unique structural characteristics. In actual use, it has been found that forged steel cold rolls do have better thermal crack resistance than high chromium cast iron rolls. Therefore, in the event of a general production accident, the impact of the accident can be eliminated by normal grinding or by adding a small amount of grinding, which simplifies the process and saves costs.

7. Good Wear Resistance.

Compared with semi-steel, high-chromium cast iron, and high-nickel-chromium infinite chilled cast iron rolls, the tonnage of forged steel cold roll rolling is greatly improved, the F1-F4 frame is about 10000t, and the F5 frame is about 6000t, showing forged steel cold. The rolls have good wear resistance. The increase of tonnage of forged steel cold roll rolling results in a significant decrease in roll consumption. Under the same rolling conditions, the roll consumption of forged steel cold roll is 1/5 of that of high chromium cast iron roll in F1 frame, and F2 frame is high chromium. The 1/7, F4 frame of the cast iron roll is 1/13 of the high nickel-chromium infinite chill cold work roll and the cold roll intermediate roll, and the F5 frame is 1/8 of the high nickel-chromium infinite chilled cast iron roll.

Free send inquiries to [email protected] or [email protected] if any needs.

Whatsapp/Wechat:+8615877652925

Website: https://www.hanrm.com

Article Resource: Characteristics of Forged Steel Cold Rolls (Cold Rolling Work Rolls, Cold Rolling Intermediate Rolls)

More News You May Interesting:

The Cause of Rolling Mill Rolls Breakage

Material Selection of Rolling Mill Rolls

Failure Analysis of Cold Mill Roll

Design of Mill Rolls for Rolling Mill and Material of Rolls

Development of High-speed Steel Rolls

New Process Sendzimir Roll Features

Sendzimir Mill Roll Maintenance

Finishing Rolling Mill Process Explanation

Reasons and Solutions for the Piling of Wire Rod Rolling

Characteristics and Quality of Wire Rod

Bar Rolling Mills Water Cooling Technology

The Main Rolling Processes of the Wire Rod Mill Production Line

Laying Head of Wire Rod Mill

Headless Welding Rolling Process

How to Improve the Thermal Efficiency of the Reheating Furnaces?

Causes of Surface Cracks in High-Speed Wire Rod Rolling Mill

Cardan Shaft Assembly and Routine Maintenance

Causes and Solution of Steel Piling-up in High-speed Wire Rod Rolling Mills?

Why does the Steel Bar Bend after being Cut by Flying Shear?