Most Popular

Advantages and Disadvantages of Electric Arc Furnace and Induction Furnace Steelmaking

Advantages and Disadvantages of Electric Arc Furnace and Induction Furnace Steelmaking

Electric Arc Furnace VS Induction Furnace SteelmakingComparison of advantages and ...

Electric Arc Furnace VS Submerged Arc Furnace

Electric Arc Furnace VS Submerged Arc Furnace

Electric Arc Furnace VS Submerged Arc Furnace Direct current electric arc ...

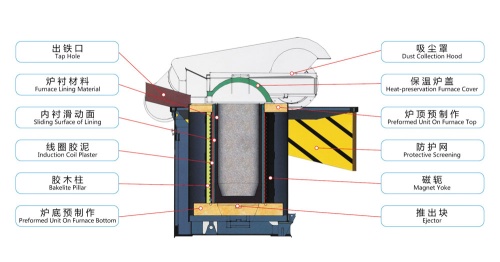

Electric Induction Furnace Diagram

Electric Induction Furnace Diagram

Electric Induction Furnace Diagram Induction furnace steelmaking is a steelmaking method that ...

Electric arc furnace steelmaking uses electric energy as heat energy and uses the high temperature of the arc generated between ...

Electric arc furnace steelmaking uses electric energy as heat energy and uses the high temperature of the arc generated between ...HAN Submerged Arc Furnace (2022-HAN Suberged Arc Furnace.pdf)

Wire Drawing Defects and Residual Stresses

Typical defects in a drawn rod or wire are similar to those observed in extrusion especially center cracking another major type of defect in wire drawing is seams, which are longitudinal scratches or folds in the material.

Seams may open up during subsequent forming operations (such as upsetting, heading, thread rolling, or bending of the rod or wire), and they can cause serious quality-control problems.

Various other surface defects (such as scratches and die marks) also can result from improper selection of the process parameters, poor lubrication, or poor die condition.

Because they undergo nonuniform deformation during drawing, cold-drawn products usually have residual stresses. For light reductions, such as only a few percent, the longitudinal-surface residual stresses are compressive (while the bulk is in tension) and fatigue life is thus improved.

Conversely, heavier reductions induce tensile surface stresses (while the bulk is in compression). Residual stresses can be significant in causing stress-corrosion cracking of the part over time.

Moreover, they cause the component to warp if a layer of material subsequently is removed such as by slitting, machining, or grinding.

Rods and tubes that are not sufficiently straight (or are supplied as the coil) can be straightened by passing them through an arrangement of rolls placed at the different axe.

Article Source: Wire Drawing Defects and Residual Stresses

More Articles You May Interesting:

Automatic Wire Drawing Machine VS Manual Drawing Machine

Automatic Nail Making Machine Working Principle

Cemented Carbide Wire Drawing Die Manufacturing Process

Precautions for Wire Drawing Machine Operation

Wire Drawing Machines: Spray Welding VS Tungsten Carbide Thermal Spraying

What is Elephant Trunk Take-up Machine?

Six Types Wire Drawing Machines

Copper Wire Drawing Machine Production Process

Wire Drawing Machine Structure Device

Advantages of Inverted Wire Drawing Machine

High Speed Wet Wire Drawing Machine Operation Steps

Wire Drawing Products Unqualified Surface Quality Reasons

Wet Wire Drawing Machine Working Principle

Wet Drawing Machine Transformation Process Requirements